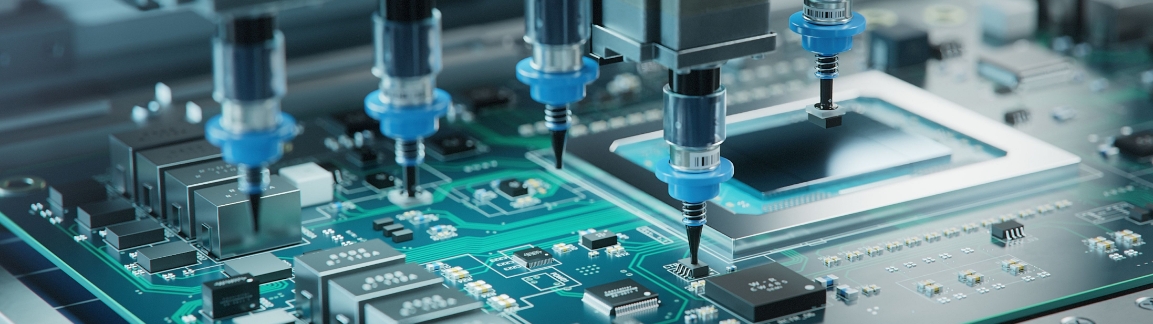

- Renovation of the mounting capacity of the ultra-long board (1.2 meters long) of the placement machine

- Dispensing machine extra-long board (1.2 meter board length) mounting capacity modification.

- Installation and modification of the Feeder Station on the rear side of the placement machine

- The placement machine is equipped with a fixed camera or a left MARK recognition camera.

- SMT flow direction transformation

- SMT special-shaped nozzle customization

- SMT OPTION installation (including MES docking) and modification.

- Modification of the code scanning capability at the bottom of the placement machine

- Reflow soldering fixed side modification.

- Reflow soldering area nitrogen filling modification.

- Reflow soldering adjacent area temperature difference of more than 70 degrees modification.

- Reflow soldering cooling zone cooling capacity enhancement and transformation.

- Reflow soldering MES docking, product tracking data output transformation.

- Reflow soldering PCB real-time temperature curve monitoring and tracking system installation and renovation.

- SPI/AOI MES docking, data output modification.

- SPI/AOI bottom scanning capability retrofitted.

Contact information

Hong Kong Technical Services Headquarters

- Contact Person:Mr. Chan

- Tel:(852) 2589 0838

- Email:kchan@ese.com.hk

South China Technical Service Centre

- Contact Person:Mr. Shui

- Tel:(86) 755-83760258

- Email:ghshui@sz.ese.com.hk

East/Southwest China Technical Service Centre

- Contact Person:Mr. Xu

- Tel:(86) 21-61339706-311

- Email:vernxu@sh.ese.com.hk

North China Technical Service Centre

- Contact Person:Mr. Wang

- Tel:(86) 10-68588108-217

- Email: junwang@bj.ese.com.hk